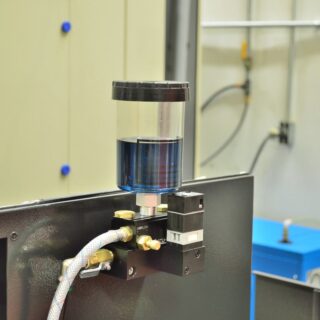

We use a custom micro air/oil programmable coolant/lubrication system that we have developed and installed on all of our cnc mills and our Mazak cnc lathe. The programmable nozzles automatically adjust to tool length and disperse a fine mist of vegetable oil and air. This system is not only extremely friendly to the environment and our employees, but it also extends tool life.

Amada CNC Band Saw. It will cut stock up to 10 inches in diameter and hold a stock feed length tolerance of plus or minus 0.002 inches.

You can see some of the custom modifications made to the saw. Like our CNC mills, we have adapted it to use micro air/oil lubrication. This type of lubrication is not only much more environmentally friendly than standard coolant, but it also extends machine and blade life.